CIO Blogs: Sharp Takes for Future Stakes

Bold opinions to challenge IT leaders and ignite visionary thinking.

Managing Enterprise Architecture for Value

The objective of governance is to ensure delivery of business value. Enterprise Architecture Governance aims to do just that – ensure delivery of business value

Changing Organizational Culture in Support of Digital Transformation

Of the three, people, processes, and technology, perhaps the toughest to change is: people. Regrettably, business transformations pay the least amount of attention to this

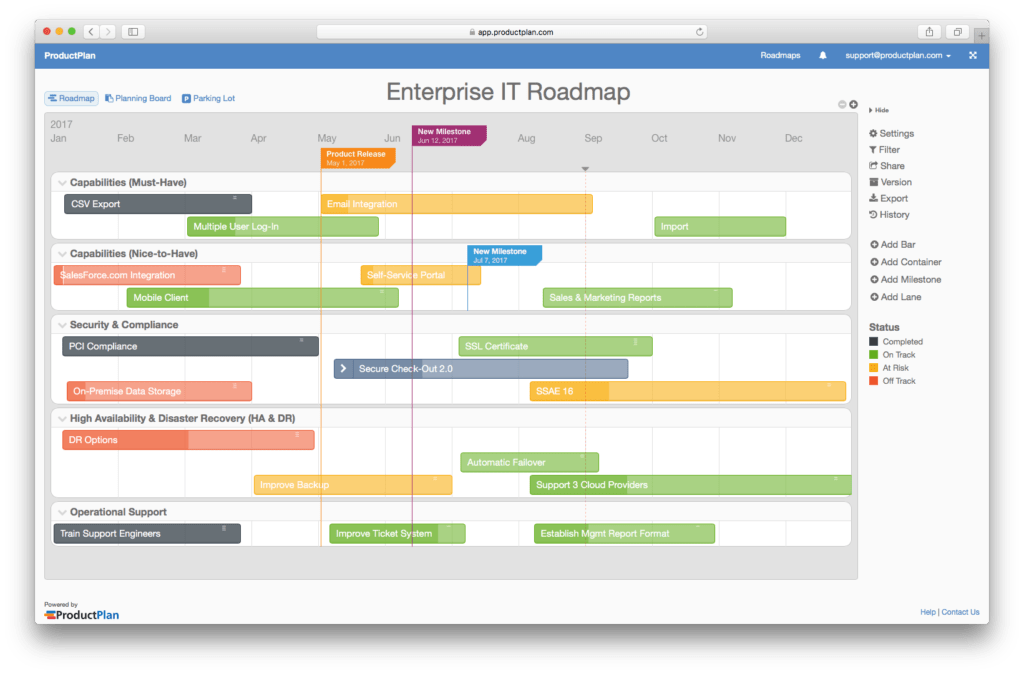

Understanding the Role and Purpose of Roadmaps in IT Projects

Roadmaps are more than just planning tools; they’re strategic compasses. This article sheds light on the pivotal role and purpose of roadmaps in guiding IT projects to success.

e-Book: Practical Enterprise Architecture for Business Value

There is enterprise architecture. Then, there is practical enterprise architecture. The former is charts and graphs. The latter is business value delivered on a platter.

E-Book: Six Sigma Explained

IT Governance is a blunt instrument unless supported with quantitative analysis and tools. Fortunately, CIOs can borrow these tools from other disciplines. Six Sigma is

e-Book: IT Post Merger Integration Best Practices

CIOs play a critical role in mergers and acquisitions because often success hinges on post merger integration of information technology capabilities of the two organizations.

The Imperative for Digital Transformation

The driver(s) of change and the appetite of the target both determine the best approach to business transformation. Transformations can be as simple as adapting

How to Conduct an Assessment of Your Project Portfolio Management Program?

Periodic evaluation is key to maximizing returns from an investment. Your investment in creating a Project Portfolio Management capability is no exception. The PPM program

Just Shared a Project Portfolio Management Maturity Model

Periodic evaluation is key to maximizing returns from an investment. Your investment in creating a Project Portfolio Management capability is no exception. The PPM program

Sample: Setting Technology Standards for Interoperability

Interoperability is one of the key values delivered through Enterprise Architecture. Standards are the key to interoperability. CIOs must understand the value of standards, how